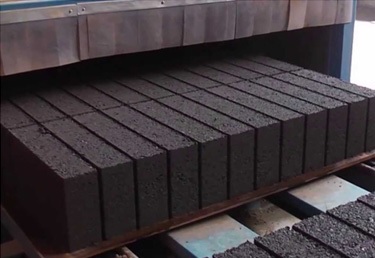

Carbon Bricks

Carbon Bricks

Acid Services are following below:

- Acid Resistant Tile Lining (ARTL)

- Acid Resistant Brick Lining (ARBL)

- Acid Resistant Carbon Brick Lining

⦁ Carbon Bricks are used as linings in high temperature vessels and corrosive environments with acid/alkali attack. Carbon bricks can withstand most chemical attacks, high temperatures or sudden temperature changes, thermal shock associated with vessels of such conditions.

⦁ Carbon bricks & Carbon tiles are recommended for hydrofluoric acid, hydrofluorosilicic acid, their salts and caustic environments. The characteristics of carbon brick have proved outstanding in numerous areas of the chemical industry for the lining of baths, lining of chambers and towers in chemical plants, reaction vessels and boilers as well as corrosion resistant masonry construction and floor coverings.

⦁ Carbon bricks/ tiles / shapes / sleeves are supplied in grades manufactured using the latest production techniques as per IS, ASTMC 1160 or DIN standards.

Major Application Areas (Graphite carbon brick)

⦁ Carbon bricks are not only widely used in the metallurgical industry, but also in aluminium electrolysis cells. In addition, it is widely used in pickling tanks and electroplating tanks in electroplating industry, dissolution tanks in papermaking industry, reaction tanks and storage tanks in chemical industry, autoclave in petrochemical industry, ferroalloy industrial furnaces (or equipment linings), acid and alkali tank linings and pipelines, and furnace linings for smelting non-ferrous metals (such as aluminium, lead, tin, etc.).

- Mandana Stone Lining

- FRP Lining

- Epoxy Coating

- Mastic Lining

- Rubber Lining

Insulation Services :

Production :

Acid Resistant Bricks

⦁ We are supplier of high-quality acid resistant bricks, acid proof bricks, chemical resistant brick, anti-acid bricks, acid alkali resistant bricks exporter in india. Our acid resistant bricks are used for masonry constructions and floorings subject to acid attack, lining of chambers and towers in chemical plants, lining of sewers carrying industrial effluents and to prevent deterioration of the surface by acids except hydrofluoric acid and perchloric acids.

⦁ Acid resistant bricks are made of raw materials, such as clay of suitable composition with low lime and iron content, feldspar, flint or sand and vitrified at high temperatures in ceramic kilns. Durachem bricks are normally installed with chemical resistant mortars. They are available in different sizes and shapesbedded and jointed with acid proof cements. The cements used are depending on the chemical condition and temperature up to its specific limitations. We manufacture as per relevant IS/ASTM standards.

Applications Industries

- Chemical Plants

- Dairy food and beverages

- Iron & Steel Plants

- Petrochemical Plants

- Oil & Gas Refineries

- Pulp & paper Industries

- Thermal Power plants

- Battery Manufacturing Unit

- Automobile & Ancillary Unit